VE7BQH

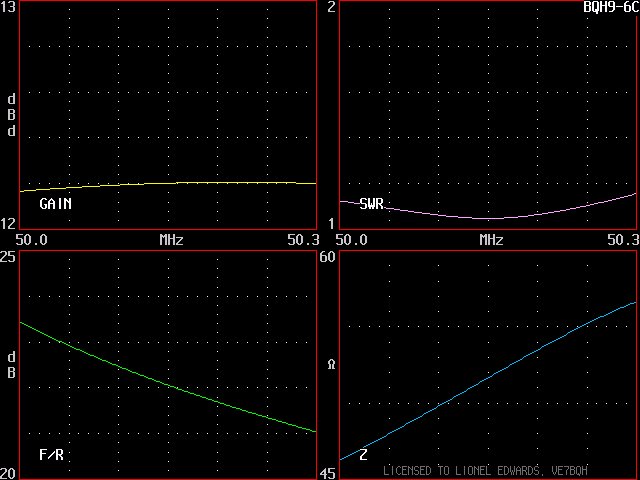

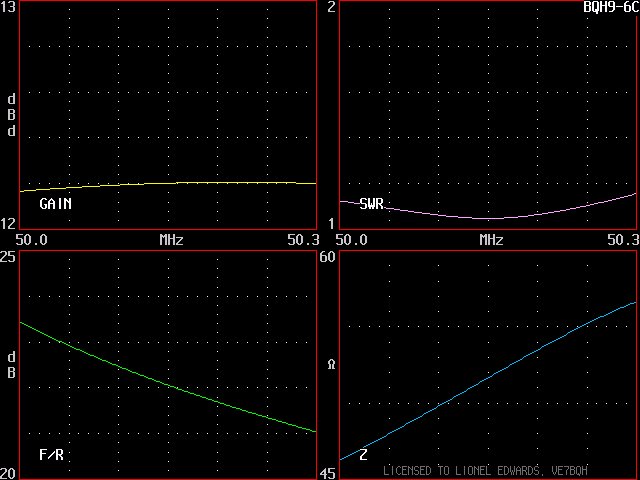

BQH9-6c 50 MHZ YAGI

DESIGN

The "BQH9-6c"

Antenna - A 9 Element Yagi for 50.150 MHz with 12.2 dBd gain, and

a 50 ohm direct feed (thanks to W1IPL for finished antenna photos)

This antenna was designed to be an easily-constructed, very strong and

durable antenna, with over 12 dB gain (compared to a dipole), and

capable of being used effectively for EME contacts when aimed at the

horizon. With the use of weak signal digital modes, this antenna

should be able to produce contacts with larger stations, even while

elevated off the horizon. A pair of these antennas, or an array

of four such antennas, would make an excellent steerable 6m EME array.

NOTE: The details

of this design must be followed strictly to obtain the anticipated

performance. In other words, you MUST

use the same spacing and mounting of the insulated elements, the same

element diameters, the correct lengths shown, etc.

Many thanks to the efforts of VE7BQH for his fine contribution,

diagrams and notes, which are shown below.

The "BQH9-6C"

Construction Notes

1) BOOM

material

is assumed to be 2" diameter aluminum tubing, although slight

variations in diameter are not considered significant.You will need to

plot the element locations on paper versus the joints in the boom, to

make sure no elements end up on a transition joint.

It is normally a pretty easy thing to adjust the transition joint to

not

coincide with an element by either moving where the antenna starts on

the

boom or changing where the joint happens.

2) TRUSSING of

the boom at right angles to the elements can be done as required, with

turnbuckles and steel cable to keep boom sag minimal. Any lines

added to reduce side-to-side bending in the plane of the elements

should be done with non-conductive material such as Phyllistran, and

should be held out to the sides with non-conductive material such as

fiberglass tubing. Furthermore, any such lines should be

positioned so they do not bear down across the elements when encumbered

by ice or snow.

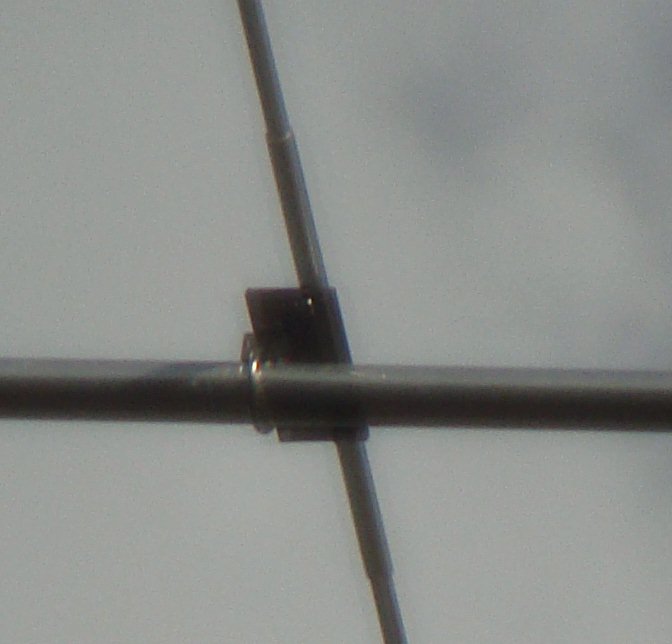

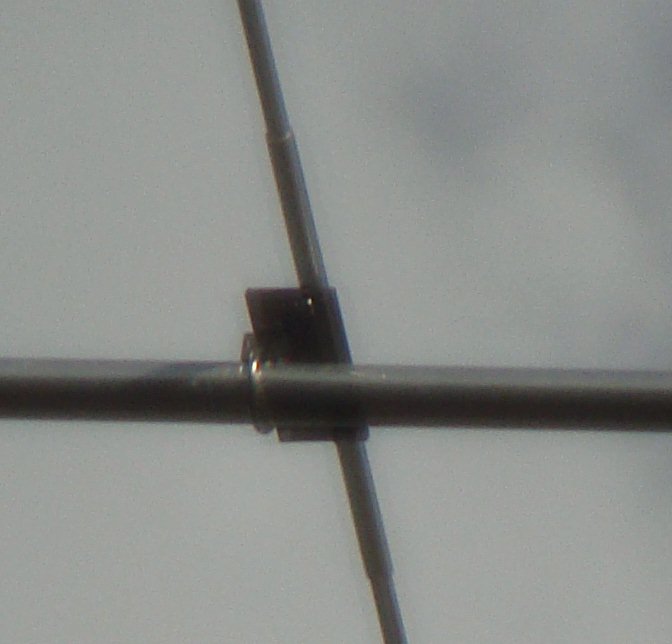

3) ELEMENT TO BOOM PLATESare

made

from

1/4" thick Lexan or HDPE insulated material. There

is no boom correction for the type of insulated element mounting used

here. That is, the boom correction is under a 1/64" and is beyond

any reasonable cutting tolerances. This assumes that you are using

small metal U bolts to fasten the elements to the lexan plates;

alternatively, you could connect the elements to the plates with a pair

of small diameter stainless steel screws and nylon locking nuts (such

as 10-32) on each side of the centerline of the plate. In eithe

case, this should introduce only a minimal disturbance (provided they

are only as long as required to hold the materials

together).

Each 1/4" thick lexan

(or HDPE) mounting plate is mounted to

the boom with a stainless steel "muffler" style clamp so the bottom of

each element

is 5/8" above the boom. This dimension IS critical. If your

particular mounting U bolt has a saddle that introduces a different

spacing, use a thicker piece of insulated plate so that the elements

are still separated from the boom by 5/8".

4) DRIVEN ELEMENT is

constructed using 1" diameter aluminum tubing, with some short sections

of 7/8" diameter tubing sticking out on each end, to allow for some

final VSWR adjustment. In addition, D1 may have to

moved slightly to adjust VSWR. It is difficult to capture every

capacitance in the program consequently the reason for some real world

touch up.

For mechanical stability, it is suggested that a 7/8" diameter piece

of teflon be inserted in the ends of the two driven element

halves, to provide good alignment and rigidity where they are attached

to the mounting plate.

5) CONNECTION OF

COAXIAL CABLE

to the split dipole must be kept as short as

possible. The inside ends of the split dipole should be no more than

1/2" apart to allow the coax connection to be kept short. VE7BQH

recommends you use crimp on spade lugs and also solder them with silver

bearing non lead solder (available in any large building supply

etc). If the antenna is going to be left installed for an

extended period of time, you can then seal all the connections with

non-taminating (non acetic acid curing) silicone.

6) FERRITE CORES

with the proper mix, such as the 1/2"

RFI CORE

(available from THE RADIO WORKS at http://www.radioworks.com), are used

to choke the RF currents in the outside of the coax. The number

of ferrites you will need is dependent on the power you will

use. 1 ferrite will handle up to 600 watts; 2 ferrites will handle 1200

watts, etc. The test is simple, the

ferrite should only be warm to the touch under sustained power. The

ferrites must be positioned as close to the feed

point as possible. As the ferrites are snap on, they need to be well

wrapped to ensure the two faces of the core are kept dry and firmly

together. Large size shrink tubing works well for this.

7) PARASITIC ELEMENTS

are constructed using center sections of 5/8" diameter tubing, with the

outer portions of each element being 1/2" diameter tubing.

8) ELEMENT LENGTHS

shown in the table below are the HALF

length.

Therefore, to obtain the overall lengths for the directors and

reflector, take the .625 length and the

.5" length, add them together and then multiply by TWO.

Example: Reflector = 12" +

46.4445" X 2 = 116.889". The

driven element is done the same way but uses the 1" and .875

diameters but will be kept in two halves.

There is no allowance shown for the extra material that will have to

be used when the smaller tubing is inserted into the larger

tubing. It is anticipated that each joint in the elements would

probably require several additional inches, and that the joints

would be secured with one or more short stainless steel screws with

nylon locking nuts.

BQH 9

Element 6 Meter

6063-T832

50.000 50.150

50.300 MHz

9

ELEMENTS,ALL DIMENSIONS SHOWN

ARE IN INCHES

SPACING

FROM

EXPOSED HALF LENGTHS OF EACH SIZE TUBING

REFLECTOR 0.6250 1.0000

0.8750 0.5000 DIAMETER OF

ALUMINUM TUBING IN INCHES

0.0000 12.0000

0.0000 0.0000 46.4445 REFLECTOR

40.0000

0.0000

50.0000 5.6407 0.0000 DRIVEN ELEMENT -

DIRECT 50 OHM FEED

62.0000 12.0000

0.0000 0.0000 42.9632 DIR 1

115.9397 12.0000 0.0000

0.0000 41.6255 DIR 2

201.3638 12.0000 0.0000

0.0000 40.5285 DIR 3

285.6098 12.0000 0.0000

0.0000 39.8537 DIR 4

385.4554 12.0000 0.0000

0.0000 39.8850 DIR 5

467.9373 12.0000 0.0000

0.0000 40.3807 DIR 6

536.0000 12.0000 0.0000

0.0000 39.0541 DIR 7

9) STACKING

BEAMS

is recommended as follows: E plane= 33.4', H plane = 30.63'

You could go down to 90% of these values with minimal gain loss.

Last updated May 22, 2010